So far, the mobile industry has relied on proprietary fast charging technology using USB Micro B connectors. But recent lithium battery events have highlighted the importance of safe power systems and USB-PD circuits.

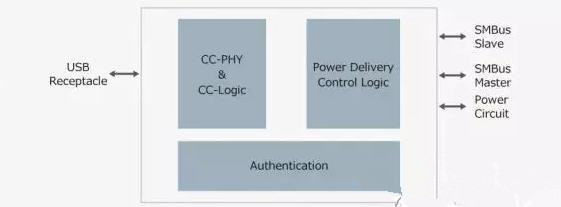

Compared to previous USB charging technologies, the USB-PD mechanism makes it easier to increase power requirements and charge compatible devices faster. And it uses a dedicated configuration channel (CC) line, independent of traditional USB data transfer.

Here are three major issues developers face when creating a fast charging app on a mobile device.

Authentication

In the USB-PD protocol, connected devices determine the optimal voltage and current levels by negotiating power requirements and signing protocols. The key requirement is that to develop USB products, manufacturers must check the true source of devices such as cables and chargers before starting high-power charging.

Authentication ensures the identity of the device, making it easier to tell if it is real or fake. Take Renesas' R9J02G012 USB controller chip as an example, which allows the USB port to be electronically authenticated, trusting the authenticity of the certificate and public key infrastructure (PKI) implemented in the USB Type-C certification specification.

Renesas claims that it has added high-intensity tamper-proof technology to its new USB port controller chip, which the Japanese chip maker has been using to protect its MCU from cyber attacks.

The R9J02G012 controller chip integrates USB PD 3.0 and USB Type-C authentication in a single package

Dimensions

Size is another important consideration in USB-PD design. For example, Renesas' USB port controller is a single package that supports USB PD 3.0 and USB Type-C certification standards.

Prior to this, these two functions were implemented with two separate chips. The single package solution reduces the mounting area of cables and electronics. According to Renesas, the new R9J02G012 USB controller has a mounting area that is 50% lower than the area used by the company's existing R9A02G011 chip. Currently, the 40-pin QFN package measures 6 mm x 6 mm and the 42-ball BGA is 3.6 mm x 3.1 mm.

This is comparable to other competing chips, such as the TPS65982 controller chip from Texas Instruments, which is also 6 mm x 6 mm.

Internal protection

USB-PD hardware requires complex interface electronics to efficiently negotiate power delivery with connected devices. For example, power output ranges from 5V/0.5A to 20V/5.0A, so built-in protection is required to avoid the risk of overvoltage.

ST's USB controller chip allows the cable to be safely disconnected using the discharge circuits of the VBUS and VCONN power lines.

STMicro's new USB Type-C port controller claims to provide internal protection without the need for an external voltage regulator, saving the number of components and boards in the USB design. The STUSB4710 controller chip handles the entire connection setup, requires no external CPU involvement, and supports up to five Power Delivery Profiles (PDOs).

USB 2.0 type A to USB 3.1 type-c with screws panel mount cable

Send your message to us:

Post time: Mar-25-2019