High Durability, Low Mating Force

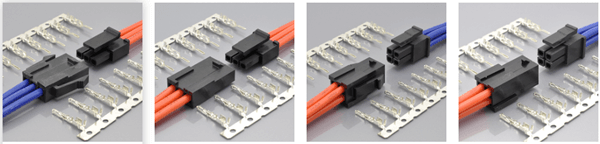

Utilizing Terminal Protection Assurance(TPA) Technology, STC manufactures Molex Micro-Fit 3.0mm with enhancements in its connector housing and contact design to help prevent connection failure. TPA designs offer overlooked connection solutions by providing locking redundancy. This promotes a durable connector design in which terminals can be inserted properly without degradation from unnecessarily exhausting them with thousands of insertions.

Equipped with Reduced Mating Force (RMF) Solutions

Reduced Mating Force (RMF) solutions are also achieved in STC Micro Fit designs with lower friction force between the contacts of the device and the socket, making insertion and removal of the device easier, while at the same time eliminating the need for the complex mechanisms such as in ZIF sockets.

Designed for Blind-Mating Applications

Micro-Fit 3.0 BMI Connectors have blind mated connections, differentiated from other types of connectors by the mating action that happens through a sliding or snapping action which can be accomplished without wrenches or other tools.

Superior Signal Integrity

This type of solution is ideal for applications where there is a need for superior signal integrity with multiple reliable and repeatable connections at 70GHz+. Blind-mated solutions are viable for systems such as the following:

- High-speed digital test head interfaces

- Probe card docking stations

- High-speed digital OEM equipment

- RF Channel system mating on testers

- Automated probing of backplane channels or high-speed signal ports

Robust and Ruggedized Terminal Enhancements

Electrical signals and power solutions are reliably conducted through connections under conditions of high current through enhanced terminal connections.

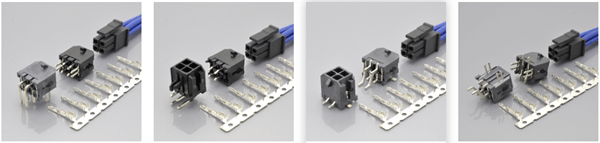

Surface Mount (SMT) Option, Press Fit (PFT), or Surface Mount Compatible Versions Available

Surface Mount (SMT) and Press Fit (PFT) both meet different needs for a broad range of electrical/electronic circuits. Press Fit Technology is often used in big connections with a reflow soldering process. Surface mounting technology (SMT) is a state-of-the-art soldering process step applying numerous electronic components to a PCB. While the SMT option is common and widely used in electronic systems, SMT has certain limitations over PFT depending on the application. STC can offer PFT or SMT options to meet your application needs.

Optimized Safety Feature for Electrical Shock Hazard

With its improved product enhancement, the connector has the capability of withstanding a voltage of 1500 V AC per minute, which means that the insulation is sufficient to protect the user from electrical shock, overheating, and fire.

User-friendly, with its completely polarized housing

STC has an improved design configuration of this connector paving an easier way for users to prevent the plug and receptacle from being mis-mated, causing stress on the connector.

Applicable in Chassis Wiring and Power Transmission Wiring

STC’s 3.0 mm Molex Micro-Fit can be used for AC and DC operations with a rated current of 5.5 amperes and 250 Volts. It is applicable in both chassis wiring and power transmission wiring.

Fully Shrouded Header

The pin header of the connector is wrapped with a thin plastic guide box around it good for preventing cable connection mishaps and it also provides good guidance for the mating connector.

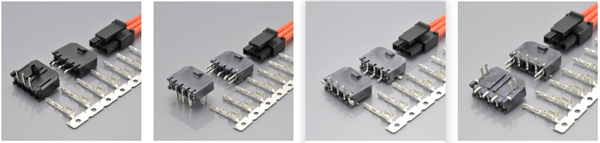

Savvy Material and Finish

The header contact is made up of copper alloy, tin plated over a phosphor bronze material.

The housing is made of Nylon66 UL94V-0 natural ivory. These housings are available with or without protrusions.

The wafer is made up of Nylon66/46 UL94V-0.

The solder tabs are made up of brass, copper undercoated, or tin-plated. These two solder tabs ensure the retention of the header to PCB connection and act as a strain relief for the SMT solder tails minimizing the chance of solder joint breakage.

Vast Temperature Range with Relatively Low Insulation and Contact resistance

There’s a dimple at the center of the contact which ensures positive contact and low contact resistance at all times. Insulation resistance and contact resistance are 1000 Mega ohm per minute minimum and 10 Mega ohm maximum, respectively.

The temperature range for this connector is -40 degrees centigrade to +80 degrees centigrade. This range is based on the rise of temperature with increasing current.